AAES is an international engineering company based in Ankara. It provides engineering, design, manufacturing, and support services to organizations in aerospace, defense, energy, and various other sectors. Our mission is to develop value-driven products and systems using advanced engineering and quality techniques, and to implement them effectively. We go beyond consultancy by embracing our clients’ goals as our own. What sets us apart is our deep technological expertise and international experience, enabling us to deliver concrete solutions. Our aim is to become a trusted partner by exceeding expectations.

The Power Control Lever (PCL) allows the pilot to manually control engine power and manage performance. By moving the PCL forward or backward, the pilot can increase or decrease the thrust produced by the engine. This enables effective power management across various flight conditions. The PCL sends signals directly to the aircraft's FADEC (Full Authority Digital Engine Control) unit. In total, three signals are transmitted via the PCL. Two of these are DC signals sent directly to the FADEC. The third signal is output as an AC signal from the PCL, which is then converted to DC by the SCU (Signal Conditioning Unit) before being forwarded to the FADEC as well.

The Smoke Mortar system is a defense unit with electronic ignition, integrable into all military vehicles. It is compatible with 76 mm munitions and features 8 launchers (4+4). It provides ammunition status feedback (loaded/empty) and ensures 45 meters, 120° coverage. Equipped with compact, ergonomic, and reliable control buttons. Fully compatible with other electronic systems and corrosion-resistant. The integrated CIT (Built-In Test) function allows for quick maintenance and fault diagnostics.

Rugged PC is a computer designed for harsh environments, developed for industrial and defense applications. It is customized for the 120 mm Mortar Fire System and features a Qt-based user interface optimized for Linux-based embedded systems. The system can be controlled via touchscreen and physical keypad. It supports both map-assisted and manual firing modes. Designed for stable performance with low power consumption, it includes dual-layer login, language selection, ammunition type/quantity selection, and a user-friendly interface. Suitable for UAV ground stations, mobile field terminals, and in-vehicle military systems.

The Vehicle-Integrated Mortar System combines high firepower and mobility, designed as a heavy-class mortar system that can be integrated into land vehicles. It is developed for missions requiring fixed base defense, forward position fire support, and rapid relocation with effective fire capability. Equipped with a semi-automatic loading mechanism, advanced fire control systems, and a range of up to 10 km, it meets the demands of modern battlefields. The system is planned to achieve a firing rate of 10 rounds per minute.

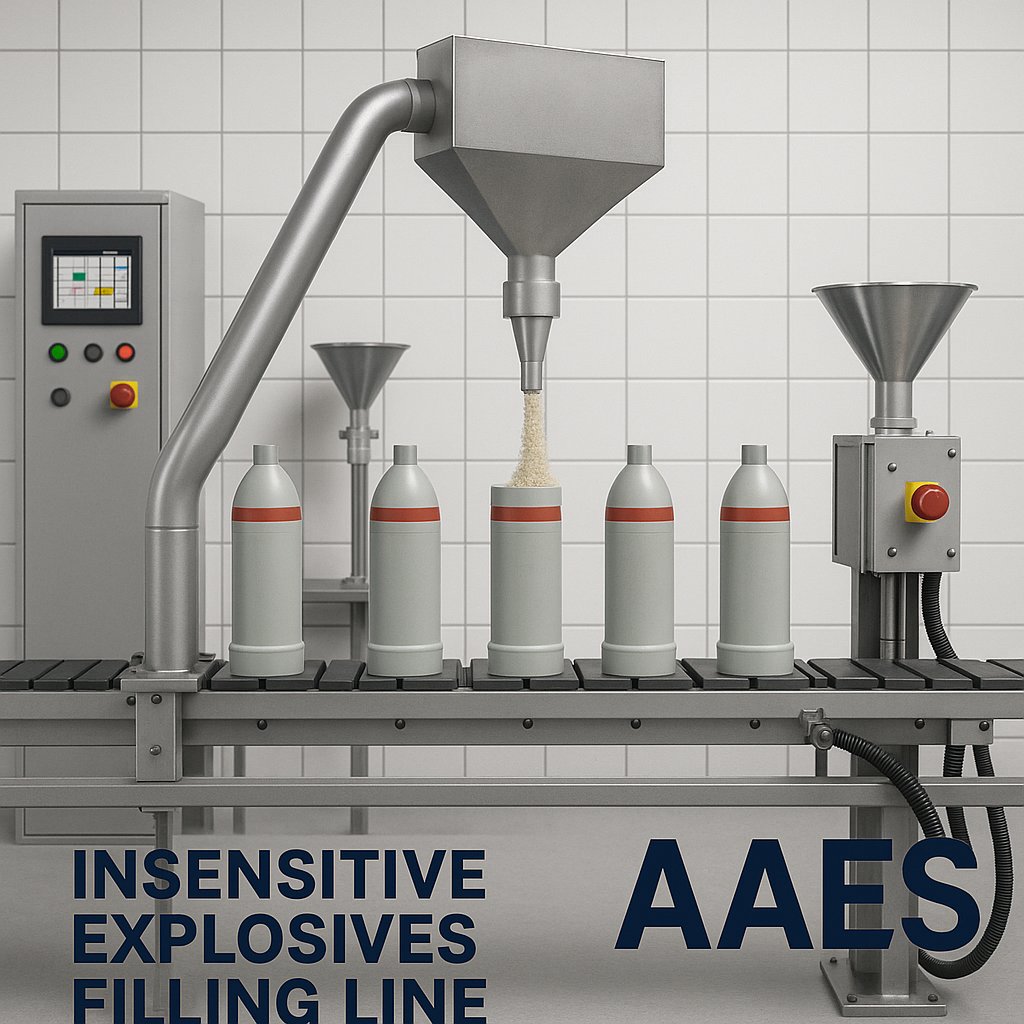

The system is capable of producing various types of ignition capsules in fully or semi-automatic modes, providing maximum control over both propellant and chemical filling processes. The production line manages all processes in an integrated manner, from raw material feeding to capsule body forming, filling, sealing, weighing, inspection, and packaging. Maximum safety is ensured through safety sensors, explosive material handling systems, inert gas-protected compartments, and ATEX-compliant equipment placed along the line. Thanks to its modular design, the system can be adapted to different types of ammunition and production capacities and is capable of manufacturing in compliance with NATO standards.

The cartridge production line performs case forming, primer insertion, propellant filling, bullet assembly, crimping, sealing, inspection, and packaging with automation support. Sensors and quality control systems ensure consistent production. Advanced propellant dosing, automatic primer feeding, and precise bullet placement maximize safety and accuracy. The system features a flexible structure adaptable to 5.56 mm, 7.62 mm, 9 mm, and various ammunition types. It offers high production speed, ATEX-compliant equipment, and NATO/MIL-STD standard compatibility.

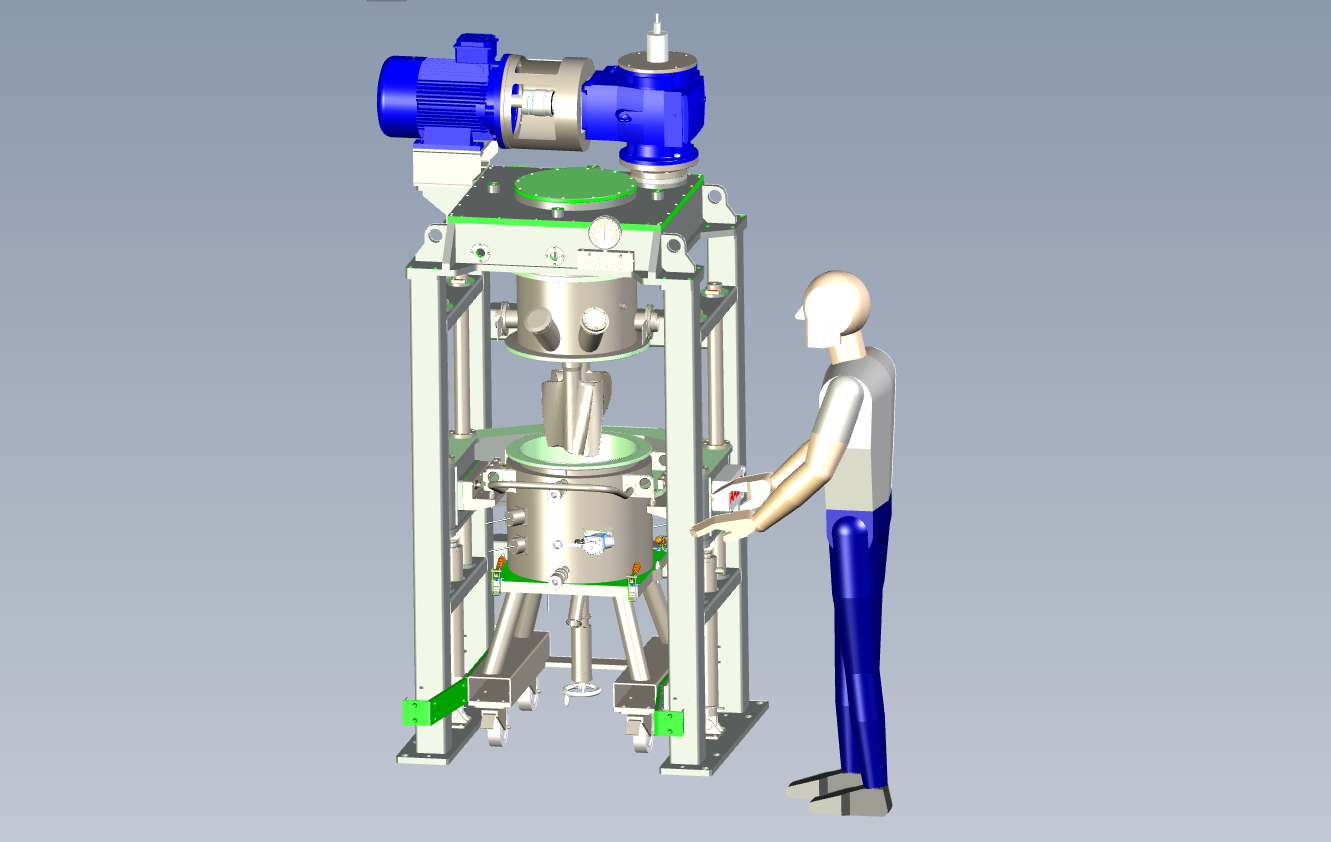

Energetic materials are high-energy compounds that release energy in a controlled way, including explosives, propellants, and pyrotechnics. They are used in military ammunition (bombs, missiles, torpedoes), rocket motors, and various industrial applications. Specialized mixers ensure homogeneous blending: planetary mixers for high-viscosity energetic materials and PBX filling, twin-screw extruders for dense energetic polymer mixtures, and cylindrical/drum mixers for simple powder blends. PBX mixing and filling systems, including planetary and polymer mixers, are designed, manufactured, and integrated for MK-series aircraft bomb production facilities.

5 and 150-Gallon Explosive Mixing Systems are designed for the homogeneous mixing of energetic filler materials, metal powders, and polymer-based explosive pre-mixtures. Featuring a compact structure and high mixing efficiency, the system is user-friendly with an operator-accessible design. The mixing unit ensures safe and effective blending through a high-torque motor and precise blade-to-mechanism clearances. A rapid pressure relief feature enhances operational safety, and the system complies with industrial safety standards.

The system performs controlled melting, transfer, filling into the product body, and subsequent cooling of TNT within a closed-loop and secure infrastructure. Throughout the process, temperature, flow, pressure, and volume are continuously monitored by precise sensors to ensure operator safety and product quality. Main Stages of the System: TNT melting unit (with controlled temperature systems) Heated and insulated explosive transfer pipelines Automatic weighing and dosing systems Filling stations (single or multiple product placement) Cooling tunnels and mold stabilization sections Final visual and weight-controlled quality inspection station

Powered by an enhanced fuel system, this drone is optimized for short- to medium-duration missions and capable of operating at high altitudes. Its gimbal-stabilized camera enables real-time object tracking and target observation. The autonomous guidance system ensures precise monitoring of designated targets, providing reliable data collection for reconnaissance and surveillance missions.